Rapier Electronic Jacquard Loom Machine

200000-500000 INR/Set

Product Details:

- Product Type Textile Machinery

- Material Iron Heavy Wall

- Machinery Type Other

- Power 3 Hp Horsepower (HP)

- Dimension (L*W*H) 16*8*10 Foot (ft)

- Weight 2200 Kilograms (kg)

- Color Green

- Click to View more

X

Rapier Electronic Jacquard Loom Machine Price And Quantity

- 2 Set

- 200000.00 - 500000.00 INR/Set

- 200000-500000 INR/Set

Rapier Electronic Jacquard Loom Machine Product Specifications

- Green

- Textile Machinery

- 1 year

- 2200 Kilograms (kg)

- 16*8*10 Foot (ft)

- 3 Hp Horsepower (HP)

- Other

- Iron Heavy Wall

Rapier Electronic Jacquard Loom Machine Trade Information

- ex factory surat

- 100 Set Per Month

- 40-45 Months

- Contact us for information regarding our sample policy

- Packaging Size 40 ft(L) * 8 ft (W) * 8 (H) Weight 18 Ton Packaging Details The normal package is wooden pallet(Size: L*W*H). the wooden pallet will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

- Australia South America Eastern Europe Middle East Central America Western Europe Asia North America Africa

- All India

- ISO 9001:2015

Product Description

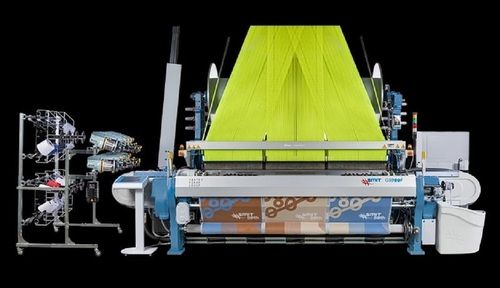

REED SPACE : 150 cm to 300 cm (60" to 120")

WIDTH REDUCTION : Minimum 4" & Maximum 20"PERFORMANCE : Filling insertion rate up to 275 m/min YARN RANGE : Spun Yarn :Ne 8.0 to Ne 120 | Filament yarns : 20 den up to 2000 den

FILLING SELECTION _ : Pick and pick selection bymechanical up to 8 colour mechanically controlled by Dobby / Jacquard

SHEDDING MOTION $: Tappet / Dobby / Jacquard

LET-OFF MOTION : Mechanical & Electrical semi positivelet-off. | Warp beam dia: up to 600 mm | Back rest : Double back rest rolls

STOP MOTION : Warp : infrared Sensor | Weft : Piezo ElectronicSensor

CUTTER : Weft Cutter : Mechanical Standard (M.S.) |Selvedge Cutter : Mechanical Standard CLOTH TAKE UP : 7 Wheel with 5 Polls |Cloth Roll Dia : up to 400 mm

MAIN DRIVE : 6-Pole ac motor with electromagnetic break

LUBRICATION : minimal manual lubrication points andremaining all friction points are fitted with self-

lubrication sealed bearings.

Important Points for Increase Rapier Loom Machine Life :

e Need electric earthing for rapier machine separately. eIt's compulsory to machine cleaning, oiling / greasing every week. e Machinefoundation must be required with chemical.

Product Details

Country of Origin | Made in India |

Usage/Application | Weaving |

Loom Dimension | 8*8*8 |

Power | 2 HP |

Color | Green |

Material | Mild Steel |

Automation Grade | Automatic |

Voltage | 700W |

Weft Selection | Electronics |

Machine Speed | 200 RPM |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electronic Jacquard' category

|

OSCARWIN WEAVING ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |